Improve Ramp Safety with the Help of an Electric or Towbarless Tug

Ground handling and ramp safety are two of the most crucial aspects of any airport. The success of an airport ramp relies on the ability of the workers to coordinate various moving parts within a small space, around extremely expensive airplanes.

As there is no single magical solution, it will require disciplined and proactive measures to maintain and improve the overall safety of your ramp. This article will reveal some of the most significant risks to ramp safety. We'll explore how to develop measures and use equipment like towbarless tugs to combat these threats.

Common Threats To Ramp Safety

As we’ve already mentioned, several factors and just as many threats come into play on an airplane ramp. The following are some of the most common issues that impact ramp safety.

Constantly Moving Obstructions

Airport ramps are buzzing with dozens of moving components at any given moment. From employees to airport tug trucks to other airplanes, ramps constantly have moving distractions. On top of this, each aircraft requires refueling, cargo movements, baggage loading and unloading, maintenance and pushbacks. With so much going on, it's easy to see how ramps can quickly become hazardous.

Jet Blasts

The area behind an idling jet can pose a significant threat to ground operators. Common ramp accidents related to jet blasts include injury to personnel, overturned ground support vehicles, damage to maintenance equipment and tools being blown around. Just the simple task of bumping the throttle up from idle in order to prepare the jet for taxi can create an extremely dangerous situation for anyone near the aircraft.

Inclement Weather

While airlines typically operate in all weather conditions, inclement weather still has a real impact on ground operations and ramp safety. Particularly brutal winter weather can lead to injuries and create hazardous circumstances for ground support vehicles.

How To Improve Ramp Safety

Increasing ramp safety is possible, but it starts with creating and cultivating a culture of safety. It also requires your organization to provide the best equipment for your ramp employees. Understand that ramp safety is an ever-changing, ever-evolving concept, so be sure to revisit your safety procedures and winter weather instructions from time to time.

Increase Communication

Inadequate communication is one of the most consistent factors in ramp accidents. A breakdown or complete lack of communication can be detrimental to your workplace safety, with the potential to turn deadly. To combat this, ramp up, encourage and maintain lines of communication between all employees.

Streamline Operations

As we’ve mentioned, at any given moment there are dozens upon dozens of moving components on a runway. A great way to improve ramp safety is to minimize these obstructions when possible in order to streamline operations. Look at your process and see if there are areas that you can improve upon and make more efficient, reducing the number of bodies, equipment and vehicles that are on the runway.

Conduct Safety Training

Inadequate training is a major cause of accidents and injuries on airport ramps. It cannot be stressed enough how important it is to incorporate proper aircraft towing procedures and safety training at your airport or hangar. A ramp is complex and constantly filled with traffic, noise and distractions. Safety training and procedures can help hone ramp workers’ skills and ensure they’re equipped with the know-how to handle any situation that comes their way.

Upgrade Ground Support Equipment

To make sure your ramp is running at peak efficiency and that you’re making the work environment as safe as possible for your employees, consider upgrading your fleet of ground support equipment.

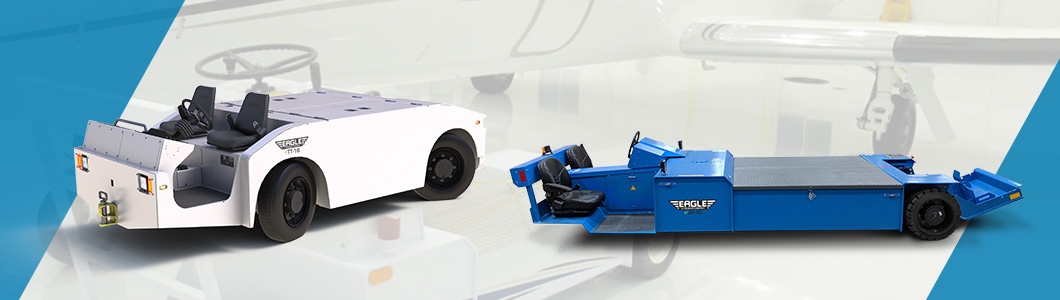

An electric tug is easy to maneuver, brakes instantly and is virtually silent. In addition to this, it gives off zero emissions, helping to cut down on local pollution and eliminating health hazards for employees and area residents in the process.

A towbarless tug does not incorporate a towbar, greatly reducing the risk of injury to crew members. This type of airport tug truck gives operators better overall visibility and maneuverability, eliminating blind spots that are more common with traditional tugs. Towbarless tugs also use a regenerative braking system, providing efficient and controlled slowing of the vehicle as opposed to sudden jolts.

Let Eagle Tugs Help Improve Your Ramp Safety

Improve the overall safety of your ramp and airport with the help of Eagle Tugs! Browse our towbarless tug selection and request a quote today. Be sure to view our airplane tug model comparison guide for an in-depth look at each type of tug we offer. Have a question or need more information? Reach out to a representative for additional assistance.

Related Articles

AIRCRAFT TRACTORS: TRADITIONAL VS. TOWBARLESS TUGS When considering what type of tractor you should buy, it can be challenging to choose between conventional or towbarless aircraft tugs. Both types of vehicle have advantages and disadvantages that largely depend on your needs and objectives. Do you want to eliminate blind spots?...

AIRCRAFT TRACTORS: TRADITIONAL VS. TOWBARLESS TUGS When considering what type of tractor you should buy, it can be challenging to choose between conventional or towbarless aircraft tugs. Both types of vehicle have advantages and disadvantages that largely depend on your needs and objectives. Do you want to eliminate blind spots?...  4 REASONS YOU MIGHT WANT TO CONSIDER AN ELECTRIC AIRCRAFT TUG While traditional diesel aircraft tugs have their place within most hangars, there is a second option that many airlines are now opting for: electric tow tugs. An electric aircraft tug has many advantages, as well as comparable features...

4 REASONS YOU MIGHT WANT TO CONSIDER AN ELECTRIC AIRCRAFT TUG While traditional diesel aircraft tugs have their place within most hangars, there is a second option that many airlines are now opting for: electric tow tugs. An electric aircraft tug has many advantages, as well as comparable features... THE TOWBARLESS AIRCRAFT TUG EJP ADVANTAGE Aircraft tugs and tractors help to keep your operation moving and making sure you have the right tools, towbars and equipment are crucial to making sure that movement is smooth. For a long time towbars have been the go-to equipment to help tow aircraft to gates, hangars...

THE TOWBARLESS AIRCRAFT TUG EJP ADVANTAGE Aircraft tugs and tractors help to keep your operation moving and making sure you have the right tools, towbars and equipment are crucial to making sure that movement is smooth. For a long time towbars have been the go-to equipment to help tow aircraft to gates, hangars...