Ensuring the well-being of your ground personnel and aircrew is imperative, and protecting your aircraft from damage could save you thousands of dollars. That's why you need to find an aircraft tug that reduces the risk of personnel injuries and towing operation accidents. Additionally, improved efficiency, maintenance and performance can save you even more in overall operational costs, especially when considering your specific demands.

To determine the superior features of either conventional or towbarless aircraft tugs, this article will delve into each tractor's attachment process, visibility, maneuverability, learning curve and braking system.

Understanding the Attachment Process for Aircraft Tugs

When it comes to choosing between conventional and towbarless tugs, the attachment process usually plays a big role in the final decision.

Traditional Tugs Utilize Aircraft Towbars

One of the most significant drawbacks of conventional towing is the attachment process. Using an aircraft towbar to physically connect the aircraft tug to the landing gear is a major reason why towbarless aircraft tugs were created in the first place. Ground personnel are tasked with connecting aircraft towbars repeatedly throughout the day – a potentially hazardous process that increases the risk for injury. Aircraft towbars for tractors are exceptionally heavy and require multiple ground personnel to get a good connection. Additionally, airplane towbars are difficult to connect correctly, and because of their weight, the process can quickly go wrong if one member gets fatigued during the connection.

But that's not the only disadvantage that comes from aircraft towbars. They also require the aircraft to be pushed/pulled at slower speeds to ensure the aircraft towbar won't disconnect during operations – meaning traditional tugs can't be used when taxiing aircraft.

Towbarless Tugs Have No Need for Towbars

In contrast, towbarless aircraft tugs do not require an airplane towbar for towing and pushback procedures. Instead, a towbarless tug connects to an aircraft by scooping up the nose wheel and lifting it from the ground. With only one crew member needed behind the wheel, this attachment process is much safer and doesn't require any other members to be in harm's way.

Another challenge associated with aircraft towbars is how many are needed for an airport. Conventional aircraft tugs often require different aircraft towbars for every individual type of aircraft. Towbarless tugs can work with pretty much any kind of aircraft without having to make adjustments for each specific aircraft model in a fleet.

Traditional aircraft tugs are only efficient for conventional towing and pushback operations when a fleet consists of only one aircraft type. In this type of situation, airports don't have to worry about the extra costs of purchasing aircraft towbars for every model in their fleet and the operational inefficiencies of constantly switching between them to tow different aircraft.

As a result, towbarless aircraft tugs are much more efficient and cost-effective than their traditional counterparts when working with various aircraft types.

How Much Operator Visibility Does Each Aircraft Tug Give You?

The ability of operators to see all around them is essential for accurate maneuverability and overall safety. Reduced visibility increases the risk of injury or an accident.

Conventional Tugs Have a Blind-Spot Problem

Conventional aircraft tugs tend to have multiple blind spots. Still, some aircraft tugs possess more visibility than others. For example, traditional aircraft towbar tugs with an open cab have more visibility than those with overhead cabs. However, even open cab aircraft tugs have multiple blind spots due to higher body design and construction.

Towbarless Aircraft Tugs Offer Better Visibility

When you look at the design of towbarless tugs, you'll notice they're generally engineered to offer better overall visibility. The lower body design of towbarless aircraft tugs eliminates more blind spots and grants drivers better operational visibility during operations. However, some towbarless aircraft tugs require the operator in the driver seat to face toward the aircraft. In some circumstances, this seat position can limit visibility.

In general, a towbarless tug provides superior visibility for towbarless pushback than traditional tractors. However, a conventional tug may offer more visibility for towing an aircraft any distance beyond being pushed out from the gate area.

Which Aircraft Tug is Better for Maneuverability?

The maneuverability of aircraft tugs is another essential factor to keep in mind during the decision-making process. With better maneuverability, aircraft are less likely to be involved in accidents – saving airports valuable time and money they can't afford to lose.

Conventional Tugs

Tugs with airplane towbars are unsurprisingly more difficult for pushback operators to maneuver. With the addition of an aircraft towbar, traditional tractors have severe pinch points and two pivot points. The maneuverability limitation of conventional aircraft tugs can place the driver station in very unusual positions and create restricted angles of vision.

Towbarless Tugs

By eliminating the aircraft towbar, maneuverability becomes unparalleled. That is precisely what towbarless pushback tugs accomplish. Towbarless tugs offer a much smaller turning radius. For operations that require tractors to work in small areas, towbarless tractors can be much more efficient.

The Difference in Aircraft Tug Braking Systems

When it comes to the safety of aircraft tugs, the braking is essential to get right – conventional and towbarless aircraft tug braking systems differ in many ways. Conventional tugs typically utilize a centralized hydraulic braking system featuring a shoe or disc brake. On the other hand, towbarless tractors use hydrostatic drive with dynamic braking.

The primary difference between dynamic and hydraulic braking systems is that dynamic braking is more efficient and cost-effective when a motor is in an overhauling condition. When an overhauling condition occurs, the motor acts as a generator and produces electrical energy from mechanical energy. The electrical energy is then released through dynamic braking systems. Dynamic braking allows tractors in an overhauling condition to make a smoother stop, especially when the operator needs to come to a halting stop during emergencies.

Another element of braking safety to think about when comparing traditional and towbarless pushback tugs is the possibility of jackknifing the aircraft when braking on a slippery surface. Conventional towing procedures are generally more at risk in inclement weather when using a traditional tug. There's always a major possibility of slipping on ice or snow if the tug is not in a straight line with the center of the aircraft's nose wheel. The further the aircraft tug is off-center, the greater the chance of jackknifing if the aircraft needs to come to an abrupt stop.

Operation & Maintenance Cost

Traditional aircraft tugs have a higher learning curve than towbarless tugs. In general, conventional tugs require more training and personnel to operate. Towbarless tractors are more friendly to inexperienced operators.

However, traditional aircraft tugs have a more straightforward design and fewer operating components despite their greater learning curve. As a result, they are easier to fix and less expensive to maintain. Towbarless aircraft tugs often require trained technicians with in-depth knowledge of hydraulics and electronics to resolve any issues and maintain day-to-day operation.

Determining the Best Aircraft Tug for Your Operation

Overall, choosing which aircraft tug is more suitable for your operation is up to you. Towbarless pushback tugs are growing in popularity, especially among airports with fleets of multiple aircraft types ready to be towed. Due to their typically improved efficiency and cost-effectiveness, towbarless tugs are excellent for large operations.

However, traditional aircraft towbar tractors are still in everyday use and can be superior to towbarless tractors depending on the specific needs of your operation. Smaller operations that only utilize one aircraft type for conventional towing might find a traditional tug more suitable.

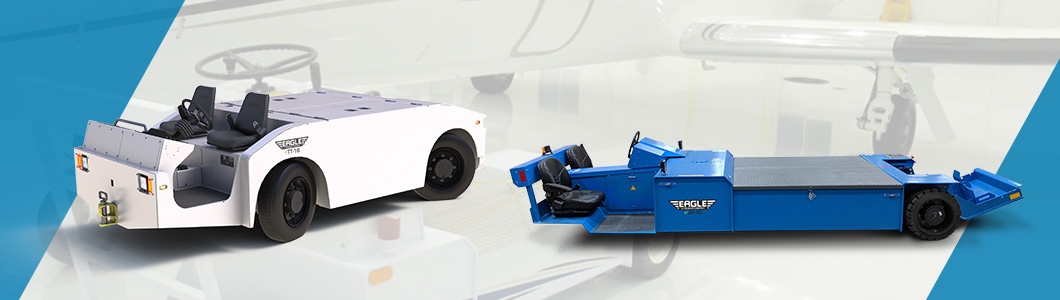

Find Traditional & Towbarless Aircraft Tugs at Eagle Tugs

After deciding on which aircraft tug tyoe is best suited for your operation, the experts at Eagle Tugs can help you find the exact conventional or towbarless tractor you need. We've been in the industry for over 50 years, designing and engineering aircraft tugs to help pilots and airports improve their operational efficiency. If you need some help deciding which is best for you, feel free to contact us at any time. We would be happy to help you determine whether a traditional or towbarless tug would most benefit your operation.

Shop Towbarless Tugs TodayRelated Articles: Traditional vs. Towbarless Aircraft Tugs

Comparing Military Aircraft Ground Support Equipment While aircraft operations are challenging for ground support equipment (GSE) at any airport, military GSE typically works under much harsher conditions. Military GSE must always be fully mission-capable and reliably work under all...

Comparing Military Aircraft Ground Support Equipment While aircraft operations are challenging for ground support equipment (GSE) at any airport, military GSE typically works under much harsher conditions. Military GSE must always be fully mission-capable and reliably work under all... 4 Reasons You Might Want To Consider An Electric Aircraft Tug While traditional diesel aircraft tugs have their place within most hangars, there is a second option that many airlines are now opting for: electric tow tugs. An electric aircraft tug has many advantages, as well as comparable...

4 Reasons You Might Want To Consider An Electric Aircraft Tug While traditional diesel aircraft tugs have their place within most hangars, there is a second option that many airlines are now opting for: electric tow tugs. An electric aircraft tug has many advantages, as well as comparable... The Towbarless Aircraft Tug eJP Advantage ircraft tugs and tractors help to keep your operation moving and making sure you have the right tools, towbars and equipment are crucial to making sure that movement is smooth. For a long time towbars have been the go-to equipment...

The Towbarless Aircraft Tug eJP Advantage ircraft tugs and tractors help to keep your operation moving and making sure you have the right tools, towbars and equipment are crucial to making sure that movement is smooth. For a long time towbars have been the go-to equipment...