The History Of Aviation Ground Support Equipment: An Aircraft Tractor Timeline

The aviation and ground support equipment industries have a naturally intertwined and storied history that dates back to the early 18th century. Through technological breakthroughs and groundbreaking developments, the way in which we maneuver aircraft through the use of aviation ground support equipment (GSE) is continuously changing and evolving.

1705 - Goldhofer Family Opens Forge In Amending, Germany

The forge continued to evolve over time and led to the first innovation center for designing and creating new mechanical concepts. The company would later go on to shift its focus to manufacturing towbarless tugs in 1987.

1914 - The Airplane Sees Use in World War I

During WWI, planes went from reconnaissance missions to full-on bombing runs. This time saw the use of early versions of ground support equipment that we use today. The GSE industry owes a debt of gratitude to the agricultural sector. Many of the machines used during this time served as a springboard for future equipment like belt loaders and deicing sprayers.

1923 - Forklift Manufacturer Creates The Duat Tow Tractor

Clark Material Handling was tasked with creating a piece of equipment that could pull freight, lumber and various industrial materials. This innovative creation has been the inspiration for many of today’s aircraft tow tractor designs.

1945-1959 - Commercial Aviation Takes Off

As military aircraft were converted into commercial planes for civilian transportation, a host of international GSE manufacturers began building specialized equipment for commercial aviation. And by 1959, the first U.S. passenger bridges were installed at San Francisco’s International Airport and New York City’s LaGuardia Airport.

1960 - Companies Begin To Shift Focus

At this time, SCHOPF began to manufacture tow tractors for airplanes based on what they’d learned from developing mining loaders.

FMC Corporation, better known today as John Bean, started to build some of the first deicer vehicles that use aerial devices to spray down aircraft. They also developed a cargo handling system for jets that allowed one person to unload a plane’s cargo in just 15 minutes.

During this time, more and more companies developed GSE equipment, most of which we still use today.

1989 - Eagle Tugs Develops All-Wheel Drive Aircraft Tractors

After the success of the Eagle Bobtail, Eagle Tugs designed a line of aircraft tugs for corporate, regional and military aircraft markets — the All-Wheel Drive (AWD) TT Series. Today, they remain the only AWD, mid-operator aircraft tugs in their class and are backed by an industry-leading 3-year/3,000-hour warranty.

2011 - The Eagle XL Series Is Released

To celebrate Eagle Tugs’ first 50 years in business, and at the request of our airline and ground handler customers, we designed a new line of commercial aircraft pushback tractors. The 4WD, 4WS Eagle XL Series has the capability to transport all single-aisle aircraft in all weather conditions.

Today and into the future, Eagle Tugs will continue to provide customers with safe, reliable aircraft tow tractors that solve the unique demands of any operation.

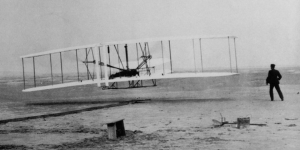

1902 - Wilbur Wright Becomes The World’s First Ramp Agent

When Orville Wright took off from Kill Devil Hills in the Wright Flyer, Wilbur was on the ground offering support for its maiden voyage. In addition to this, the Wright brothers were also using the world’s very first version of a ground power unit (GPU).

1918 - Barnstorming Becomes a New Form of Entertainment

It was during this year that daredevil pilots began to pop up across small-town America. Pilots would simply cut a deal with local farmers in order to use their farmland to perform various stunts for gathering crowds. Before they were famous aviators, Amelia Earhart and Charles Lindberg got their starts on the barnstorming circuit.

Farmers would often help to tow the airplanes using their tractors. That is why today we refer to a piece of aircraft towing equipment as an aircraft tractor.

1935 - E. P. Grime Founds The Malabar Machine Co.

This machine shop was known for creating items from customer’s custom drawings. Just a few years after starting, Lockheed (better known today as Lockheed Martin) put in an order to Grime to build the first tripod jack made specifically for airplanes.

1944 - Aircraft Manufacturing Reaches Peak Production

At the start of World War II, the U.S. had just 3,600 military aircraft. By the end of the war, military aircraft production had reached nearly 300,000. During this time, a real market for ground support products began to emerge.

1963 - A Full Line of GSE Parts Hits the Market

It’s at this time that U.S. Airmotive GSE began manufacturing a full line of parts and supplies for aircraft ground support equipment industries.

1969 - Eagle Tugs Creates The First Bobtail Cargo Tractor

In this year, airlines put out a call for an all-weather, high-speed cargo tractor — Eagle Tugs answered that call. We successfully engineered and developed the Ford F-350 Bobtail for United Airlines at Detroit Metropolitan Airport. Within just two decades, Eagle Tug’s Bobtail Cargo Tractor would become the narrow and wide-body cargo towing standard used by all military GSE, as well as all North American and British airlines. Today, the Bobtail Truck remains the leading high-speed cargo tractor around the world.

2009 - Eagle Tugs Goes Electric

To complement the popular TT Series, Eagle Tugs introduced the 4WD, 4WS 80V A/C electric aircraft tractor, better known as the ETT Series. This new line offered customers a zero-emission alternative to diesel-only models.

1705 - Goldhofer Family Opens Forge In Amending, Germany

The forge continued to evolve over time and led to the first innovation center for designing and creating new mechanical concepts. The company would later go on to shift its focus to manufacturing towbarless tugs in 1987.

1902 - Wilbur Wright Becomes The World’s First Ramp Agent

When Orville Wright took off from Kill Devil Hills in the Wright Flyer, Wilbur was on the ground offering support for its maiden voyage. In addition to this, the Wright brothers were also using the world’s very first version of a ground power unit (GPU).

1914 - The Airplane Sees Use in World War I

During WWI, planes went from reconnaissance missions to full-on bombing runs. This time saw the use of early versions of ground support equipment that we use today. The GSE industry owes a debt of gratitude to the agricultural sector. Many of the machines used during this time served as a springboard for future equipment like belt loaders and deicing sprayers.

1918 - Barnstorming Becomes a New Form of Entertainment

It was during this year that daredevil pilots began to pop up across small-town America. Pilots would simply cut a deal with local farmers in order to use their farmland to perform various stunts for gathering crowds. Before they were famous aviators, Amelia Earhart and Charles Lindberg got their starts on the barnstorming circuit.

Farmers would often help to tow the airplanes using their tractors. That is why today we refer to a piece of aircraft towing equipment as an aircraft tractor.

1923 - Forklift Manufacturer Creates The Duat Tow Tractor

Clark Material Handling was tasked with creating a piece of equipment that could pull freight, lumber and various industrial materials. This innovative creation has been the inspiration for many of today’s aircraft tow tractor designs.

1935 - E. P. Grime Founds The Malabar Machine Co.

This machine shop was known for creating items from customer’s custom drawings. Just a few years after starting, Lockheed (better known today as Lockheed Martin) put in an order to Grime to build the first tripod jack made specifically for airplanes.

1944 - Aircraft Manufacturing Reaches Peak Production

At the start of World War II, the U.S. had just 3,600 military aircraft. By the end of the war, military aircraft production had reached nearly 300,000. During this time, a real market for ground support products began to emerge.

1945-1959 - Commercial Aviation Takes Off

As military aircraft were converted into commercial planes for civilian transportation, a host of international GSE manufacturers began building specialized equipment for commercial aviation. And by 1959, the first U.S. passenger bridges were installed at San Francisco’s International Airport and New York City’s LaGuardia Airport.

1960 - Companies Begin To Shift Focus

At this time, SCHOPF began to manufacture tow tractors for airplanes based on what they’d learned from developing mining loaders.

FMC Corporation, better known today as John Bean, started to build some of the first deicer vehicles that use aerial devices to spray down aircraft. They also developed a cargo handling system for jets that allowed one person to unload a plane’s cargo in just 15 minutes.

During this time, more and more companies developed GSE equipment, most of which we still use today.

1963 - A Full Line of GSE Parts Hits the Market

It’s at this time that U.S. Airmotive GSE began manufacturing a full line of parts and supplies for aircraft ground support equipment industries.

1969 - Eagle Tugs Creates The First Bobtail Cargo Tractor

In this year, airlines put out a call for an all-weather, high-speed cargo tractor — Eagle Tugs answered that call. We successfully engineered and developed the Ford F-350 Bobtail for United Airlines at Detroit Metropolitan Airport. Within just two decades, Eagle Tug’s Bobtail Cargo Tractor would become the narrow and wide-body cargo towing standard used by all military GSE, as well as all North American and British airlines. Today, the Bobtail Truck remains the leading high-speed cargo tractor around the world.

1989 - Eagle Tugs Develops All-Wheel Drive Aircraft Tractors

After the success of the Eagle Bobtail, Eagle Tugs designed a line of aircraft tugs for corporate, regional and military aircraft markets — the All-Wheel Drive (AWD) TT Series. Today, they remain the only AWD, mid-operator aircraft tugs in their class and are backed by an industry-leading 3-year/3,000-hour warranty.

2009 - Eagle Tugs Goes Electric

To complement the popular TT Series, Eagle Tugs introduced the 4WD, 4WS 80V A/C electric aircraft tractor, better known as the ETT Series. This new line offered customers a zero-emission alternative to diesel-only models.

2011 - The Eagle XL Series Is Released

To celebrate Eagle Tugs’ first 50 years in business, and at the request of our airline and ground handler customers, we designed a new line of commercial aircraft pushback tractors. The 4WD, 4WS Eagle XL Series has the capability to transport all single-aisle aircraft in all weather conditions.

Today and into the future, Eagle Tugs will continue to provide customers with safe, reliable aircraft tow tractors that solve the unique demands of any operation.

Contact Eagle Tugs Today For Your New Aircraft Tow Tractor

When it comes to aviation ground support equipment, Eagle Tugs is an industry leader. Our mission is to provide our customers with high-quality aircraft tractor tugs that are safe, efficient and reliable. Browse our selection of Bobtail tractors, towbarless tug models and more, and reach out for a custom quote. If you have a question or want to know more about our GSE options, contact Eagle Tugs today!

Contact Us TodayRelated Articles

GROUND SUPPORT EQUIPMENT FOR AIR CARGO TRANSPORT AND TOWING Many of the products we use daily would not be accessible to us without air cargo transport and the air cargo handling equipment used in the process. In addition to the 3 billion passengers who fly yearly, over 52 million metric tons of freight are transported worldwide. Here's a closer look at what air cargo transport involves and the best ground support equipment to keep it running efficiently.

GROUND SUPPORT EQUIPMENT FOR AIR CARGO TRANSPORT AND TOWING Many of the products we use daily would not be accessible to us without air cargo transport and the air cargo handling equipment used in the process. In addition to the 3 billion passengers who fly yearly, over 52 million metric tons of freight are transported worldwide. Here's a closer look at what air cargo transport involves and the best ground support equipment to keep it running efficiently.  TYPES OF AIRPLANE TUGS, FROM SMALL AIRCRAFT TUGS TO ELECTRIC TOWBARLESS TRACTORS An airplane tug is used to prepare an aircraft for take-off or transport a craft for regular maintenance and repair. It's a crucial component of any airport or hangar's ground support equipment (GSE). In this article, we're taking a look at some of the more common types...

TYPES OF AIRPLANE TUGS, FROM SMALL AIRCRAFT TUGS TO ELECTRIC TOWBARLESS TRACTORS An airplane tug is used to prepare an aircraft for take-off or transport a craft for regular maintenance and repair. It's a crucial component of any airport or hangar's ground support equipment (GSE). In this article, we're taking a look at some of the more common types... PREVENTIVE MAINTENANCE PROCEDURES FOR AIRPLANE TUGS Regular maintenance and repairs are necessary for airplane tugs in order to avoid costly damage and downtime — this includes preventive maintenance. The term “preventive maintenance” encompasses taking measurements, running tests, cleaning, lubricating, repairing, replacing aircraft tug parts...

PREVENTIVE MAINTENANCE PROCEDURES FOR AIRPLANE TUGS Regular maintenance and repairs are necessary for airplane tugs in order to avoid costly damage and downtime — this includes preventive maintenance. The term “preventive maintenance” encompasses taking measurements, running tests, cleaning, lubricating, repairing, replacing aircraft tug parts...